Cutter II 510

Description

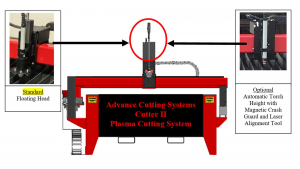

The Cutter II cutting system was introduced to the market in 2006 as the latest model in the Advance Cutting Systems product line. The Cutter II is a state of the art Computer Numerically Controlled (CNC) Cutting System designed to use a plasma-cutting torch to cut out geometrical shapes and parametrically programmed HVAC (Duct Work) fittings. The fittings are programmed in the office using Profile Master PM-2000 Duct-CAM (Computer Aided Manufacturing) software; the parts are then nested on a sheet of metal to minimize material waste and are then cut out at high speed with the plasma torch.

Cutting Table Features:

- 5′ x 10′ Cutting Area, Single Piece, Unitized Design

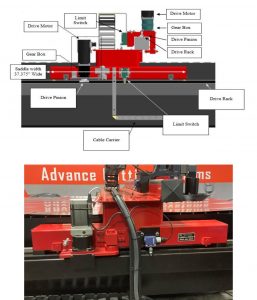

- Direct Drive Rack & Pinion (NO BELTS)

- Extra Wide Drive Side Saddle adding stability to long axis cutting

- Planetary Gear Boxes

- High Speed Traverse

- ACS Color Graphic Controller with Motors and Drives

- Hypertherm Plasma

- Floating Head

- AutoDesk Fabrication CAMduct Software with all fittings and nesting

- Office Computer with Printer allowing for programming of Jobs in the office

- Multiple copies of Remote Date Entry for field programming

- Onsite Installation and Training including all travel and labor expenses

- The Cutter II is MADE IN THE USA!

- Free Phone, Email & Remote Support to the original owner for the lifetime of the machine

Table size and capability chart: Cutter II Series Size options

Torch Height Options:

Wide machine saddle for rigidity and precision:

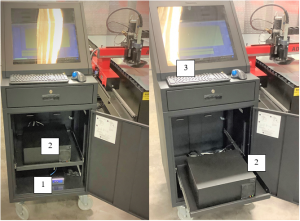

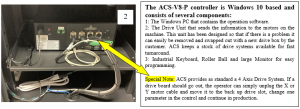

ACS – Color Graphic Control

- 20 inch Color CRT

- 4 Axis, 8 amp micro-stepping drive

- Motors

- Windows 10

- Plasma Support Interface

- Jump to Line, Dry Run

- Momentary Run

- Run File Forward and Backwards

- Kerf Crossing Detection

- DXF/DWG Import

- Automatic Kerf Compensation

- Overburn Support

- Assign Different Operations to Each Part

- Cut Sequencing

- Operation Sequencing

- Custom views of Kerf Width, Cut Direction

- Toolpath, Rapids and Part Geometry

- Customizable Post Processor

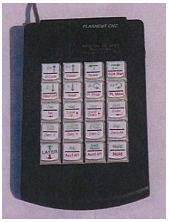

The Control Pendant allows you to move the X and Y axes. The Pendant has a 10 ft cable allowing the operator to manually position the cutting head when not in front of the Controller.

What’s inside the Cabinet of the ACS Color Graphic CNC Control?

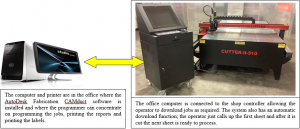

Standard Office Computer System: (connected to shop controller)

- Office Computer, Windows 10

- Large Hard Drive and RAM

- Ethernet

- Keyboard, Color Monitor, Printer

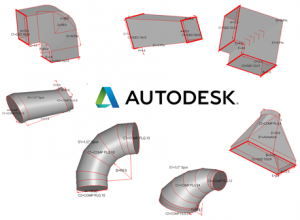

AutoDesk Fabrication CAMduct Software is installed in the office computer:

- An AutoDesk Company

- Rectangular Fitting Libraries

- Circular Fitting Libraries

- Oval Fitting Libraries

- Bought Out Fitting Libraries

- Standard Shape Library

- AutoNest & Manual Nest

- Opus-5 CAD 2-D Drawing Package

- Oversize Part Breakdown Program

- Management Reports

- Add Hole in fittings

- Perpetual License – no yearly subscription required

- Internet Help

- First-Year Software Updates Included.

- FREE phone, fax & internet support for the lifetime of the machine, to the original owner

Optional Water Table Insert with Bubbler

- Recommended for cutting material 1/2” and above. Not recommended for HVAC Contractors doing light gauge sheet metal

Optional Combo Plasma/Rotary Insulation Cutter